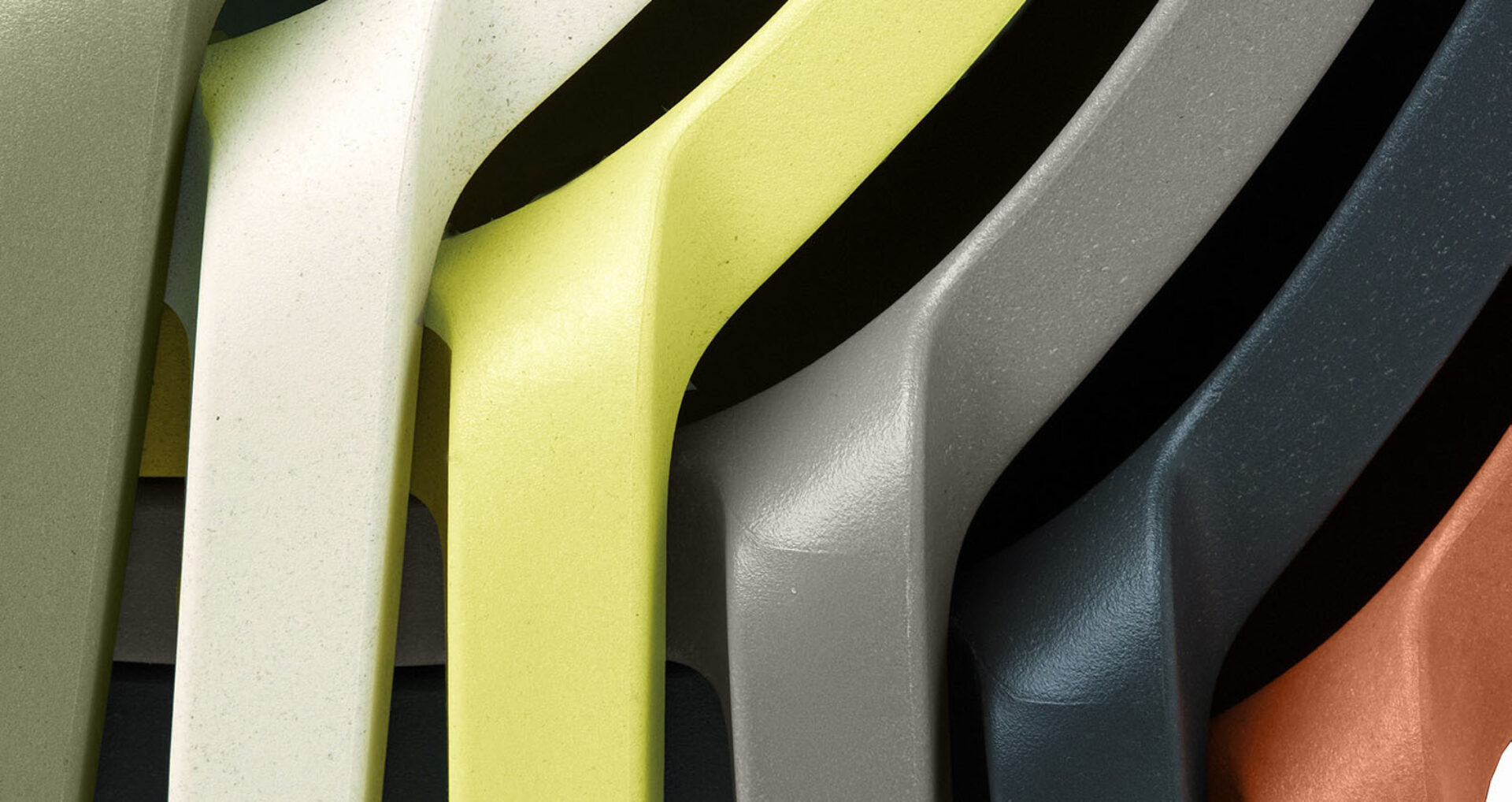

(Above image: Broom by Phillipe Starck made from 90% waste polypropylene and recycled wood fiber. Image courtesy of Emeco)

Sustainability is complex, yet imperative. Developing sustainable design solutions is crucial to the future of design—and the future of our planet. But sustainable design isn’t just about making products and spaces that reduce or erase environmental harm, it’s about ensuring that sustainability is woven into businesses’ core missions.

Take furniture maker Emeco: Founded in 1944 by Wilton Carlyle Dinges, the Electrical Machine and Equipment Company saw big business during World War II, when the company was commissioned to create a special chair for the U.S. Navy. The chair had to withstand the trials of war and life at sea—salt water and air, torpedo blasts, rough usage by men aboard the ships—and be lightweight, fire resistant, and otherwise extremely durable. To meet this tall order, Emeco created the 1006 Navy chair. Using scrap aluminum and a 77-step process, Emeco crafted a resilient chair that was deeply sustainable and built to last, long before “sustainability” was a topic of discussion.

The challenge, though, with creating a virtually indestructible chair? “You don’t get a lot of repeat orders,” said Emeco owner Gregg Buchbinder. When he took over in 1998, the company was in dire straits. To save Emeco, Buchbinder had to tap into new markets, and he managed to do without sacrificing the company’s local presence—Emeco furniture is made in America, and has been since its beginnings, in a factory in Hanover, Pennsylvania. Sustainability, a part of Emeco’s DNA from the start, took on an even larger focus: About 90% of Emeco products are made from recycled materials.

Image courtesy of Emeco

We spoke with Buchbinder about bringing Emeco back from the brink, striking up partnerships with iconic designers like Philippe Starck, doubling down on sustainability (see the carbon footprint of Emeco collections in photo captions below), and how a relatively small company is playing a big part in shaping a more sustainable, planet-conscious built environment.

The questions all makers need to ask are: How long will it last, physically? How long will it be useful and relevant? How long will it be loved?

Gregg Buchbinder

Your dad was an engineer who worked on the structural integrity of Herman Miller furniture, and you grew up with a lot of trade show rejects, aka prototypes, around your house. What were some of your favorite pieces when you were young, and why?

Gregg Buchbinder (GB): As a kid, my favorite place to sit was on the Eames Aluminum Group lounge chair and ottoman. It was the perfect place to lean back, get comfortable, and read a book. I wasn’t tall enough for my head to reach the pillow, but I loved to pull it out of the holder on the back and flip it forward. Our family had several Eames lounge chairs. These were the most comfortable chairs in the house, and I now have them in my home. They’re still comfortable, and I love things that stand the test of time.

CEO

Emeco

Photograph by Martin Tessler

When were you first introduced to Emeco—was it when your father, the previous owner, acquired the company? What were your first impressions of Emeco?

GB: My first visit to the Emeco factory was with my dad in 1978. I was amazed by how many workshops (cutting, bending, welding, grinding, heat treating, hand finishing, and anodizing) were under one roof, how many steps there were in the process to make the chairs (77), and the incredible skill of the craftsmen. It still impresses me every time I go to the factory.

Emeco’s iconic 1006 Navy Chair was built to be incredibly durable, virtually indestructible. But in the 1940s, when Emeco got its start, we weren’t talking about sustainability yet (even though items that are built to last are more sustainable). When did Emeco really start adopting the language, practices, and overall mission of sustainability?

GB: In the 1940s when Emeco first started to make aluminum chairs, there was a shortage of raw materials, aluminum being one of them. During World War II, scrap drives were a popular way for everyone to contribute to the war effort. The 1006 Navy chair was made from scrap aluminum, and still is to this day. So, the overall practices of sustainability were always in place at Emeco. We inherited those principles from our founders and they’ve continued to guide us. We still make our aluminum chairs the same way as when we started 80 years ago, from recycled aluminum. When we started exploring additional materials in the early 2000s, I saw no reason to use anything other than recycled material—there are enough waste streams in the world.

Why is sustainability so important to your firm, and to you personally?

GB: I grew up by the ocean in California and I’ve always surfed and sailed a lot. I still spend a lot of time in the ocean, and it’s important to me to protect this habitat. One of our core values at Emeco is to have the least impact possible on the planet. All of us at Emeco do our best to preserve the planet and our natural resources, through our work and in our personal lives.

Image courtesy of Emeco

Image courtesy of Emeco

Emeco was on the brink of being shut down when you took over the company. What inspired you to take on the challenge? How did you figure out how to discover a new market and save the company?

GB: The problem with making a virtually indestructible chair that lasts forever is that you don’t get a lot of repeat orders. But I felt strongly that there had to be a future for this remarkable company, with its unique history, unbelievable craftsmanship. and intricate process. I looked through the order books and noticed some orders for cool hotels, very different from the usual U.S. military and government applications. One of the orders was for New York City’s Paramount Hotel, by a designer called Philippe Starck [who redesigned the hotel’s common areas in the late 1980s]. I decided to pursue that. I figured we had such great products, we just needed to find new customers. So, I went to New York and went door to door to design stores. As chance would have it, I bumped into Philippe Starck in a corridor at ICFF [the International Contemporary Furniture Fair]. I thanked him for choosing our chairs for the Paramount Hotel, we clicked, and the rest is, as they say, history.

Emeco has partnered with the likes of Starck, Frank Gehry, and Naoto Fukasawa. What have you learned from working with these designers, and what most surprised you during these collaborations?

GB: Each collaboration with a designer has pushed us to learn new skills. Philippe Starck was the first to help us chart a new course, to transform Emeco from a military supplier to what we are today. Starck taught us the value of tenacity—he said, “If it’s difficult, just make it…if it’s impossible, I’ll redesign it.” He also wanted us to produce a chair with a highly reflective polished finish for Ian Schrager’s [since closed] Hudson Hotel in New York. We had never done that, so I got our neighbors at Harley Davidson in York, Pennsylvania, to show us how to hand polish aluminum. It takes us eight hours per chair, but the result is a gleaming surface that makes the chair look like a piece of jewelry.

We delivered 1,000 Hudson chairs to the hotel in 2000; all of them outlasted the hotel and found new homes when the hotel closed in 2022. That’s something I’m very proud of. Frank Gehry told us a chair is about the hardest thing to make. His design was a chair using flexible aluminum for comfort. Gehry was right, a chair is about the hardest thing to make, especially if it flexes. Naoto Fukasawa designed a very simple aluminum stool, Za. His attention to every detail was impressive and his vision to design a stool that would “give people a happy mood when sitting” really resonated with me.

Image courtesy of Emeco

Image courtesy of Emeco

Image courtesy of Emeco

Image courtesy of Emeco

One thing that seems to stand out about Emeco’s manufacturing process is your level of detail. Building the 1006 Navy chair requires 77 steps. What else differentiates Emeco’s manufacturing process? How is your approach different from other companies?

GB: What sets Emeco apart is that we still make everything under one roof, in Hanover, PA, and we still build our chairs by hand. When Philippe Starck first visited our factory, he told our craftsmen that their most important tools are “hands, eyes, and hearts.” They still are. Emeco is an expert when it comes to aluminum. This extraordinary material is not only superior to all others when it comes to sustainability, but also lifespan—and it’s beautiful. We take this recycled material and transform it with the painstaking work of our craftsmen to create elegant furniture which stands the test of time. For three generations, Emeco is and has been a family-owned creative, innovative, and responsible company, maintaining its production in America with worldwide distribution.

Almost 90% of your products are made from recycled materials. How did you get there?

GB: We never looked for the easiest or cheapest way to build our furniture. We opted for what we believed were the best and most responsible materials and methods to build furniture that lasts. We’ve always used recycled aluminum, and that’s still our core material. That inspired us to explore recycled plastics. In 2010, we launched the 111 Navy chair, which at the time was the world’s first chair made from recycled plastic bottles. It took us four years of development to turn the soft plastic into something structurally sound, so you need to take a long view and have a vision that goes beyond just selling products. Today, we use recycled PET [polyethylene terephthalate] for a range of products, and also recycled polypropylene, post-industrial waste. Wood can be trickier, but we’ve partnered with Amish woodworkers in Pennsylvania to help us source sustainable, local wood, including reclaimed barn wood, from old Pennsylvania farm buildings.

Image courtesy of Emeco

Image courtesy of Emeco

How do you choose which sustainable material to use next, and how do you monitor your products’ environmental impact?

GB: We take a holistic approach to ensure the impact of our products is as low as possible. We measure and declare carbon footprint. We use recycled materials that are in turn recyclable. We are always exploring new sustainable materials. But just as important as a material’s sustainability credentials is what you make of it; we design and build furniture to last. The most sustainable products are the ones that don’t break, don’t go out of style, and never need to be recycled. Our goal is to make useful, timeless products that you can keep for a lifetime. Many of our chairs even come with a lifetime warranty. That’s how we define sustainability.

Emeco is a relatively small company. How have you managed to make such a large impact on sustainable design?

GB: I think if you have a purpose and stay true to your values, people will recognize what you’re trying to do, and hopefully it will inspire others. The number of products Emeco sells that help divert plastic bottles from landfills and oceans is only part of the story, but if you take into account that we have inspired other companies to follow suit on the path to a more sustainable future, then you can talk about impact, and that’s really something.

What’s your take on the state of sustainability in the design industry today?

GB: There are a lot of positive efforts going on across our industry to sit lighter on the planet; material research, utilization of waste streams, designs for end- and circularity. The architecture and design community is taking great steps towards a more sustainable way of specifying products, such as the Gensler Product Sustainability Standards. As manufacturers, we all still need to think carefully about what we decide to bring into the world. Because, as great as new materials, recycling, and low carbon footprints are, all products have an impact on our planet. Longevity can help at least counterbalance that impact, over time. The questions all makers need to ask are: How long will it last, physically? How long will it be useful and relevant? How long will it be loved?

Emeco turned 80 this year. What are you most proud of when you look back on Emeco’s journey, and what are you most looking forward to in the future? What’s next for Emeco?

GB: I’m most proud that sustainability is no longer just a buzzword or trend in our industry. As our customers become more aware of the effects of climate change and diminishing natural resources, our sustainable practices have become more valued. Many companies have been inspired by our sustainability ethos. Our practices serve as a reminder of the critical role each of us plays in shaping a sustainable future. For the future, Emeco is really looking forward to continuing on our same path—still pursuing the long life high watermark of the 1006 Navy chair in future designs, and maintaining our love for the intersection of design and craftsmanship. We will continue to strive to make chairs that people love and want to keep for a lifetime.

Visit the table of contents for more Perspective: Business of Design